How to Uncover OpEx Waste in Your Maintenance Strategy

%20How%20to%20Uncover%20OpEx%20Waste%20in%20Your%20Maintenance%20Strategy.png)

April is the chief technology officer (CTO) at an enterprise that provides hosting services. Their on-premise data center comprises diverse digital assets procured over the years using a best-of-breed strategy.

In other words, the data center has a multi-vendor environment with devices at different stages of their lifespan. On top of that, they continue to utilize legacy equipment for some operations because of intricate and complex dependencies.

As the CTO, April has the decision-making powers for hardware procurement and maintenance. However, maintaining a mix of old and new devices is becoming increasingly challenging.

While April understands that she can outsource maintenance to a third party, she doesn’t want all the equipment to be maintained via third parties as many of the newer devices still have support under the OEM. The complexity of maintenance is growing, and so are the costs.

If you’re in a situation similar to April, there’s an easy solution that can simplify maintenance while keeping costs down.

It’s important to have support for critical and non-critical equipment, but without a strong hybrid maintenance strategy, it’s easy to go over budget and spend money on unnecessary OEM support. It can also result in gaps in support, and you may not have backup when you most need it.

There is a viable solution for determining which assets to put on original equipment manufacturer (OEM) support and which to put on third-party maintenance (TPM).

The Difference Between OEM Support and TPM

Maintenance is provided by the OEM on new hardware. However, all OEM equipment has a support lifecycle. At the end of that lifecycle, OEMs will no longer support the equipment or the software on the equipment. At this point, an organization may hire TPM providers for support in place of the OEM support that has expired. The dates that a piece of equipment falls off of OEM support are called "Milestone Dates."

As device lifecycles vary greatly, the OEM support may last anywhere from three to ten years. Beyond that, enterprises can only continue to maintain equipment with the help of TPM providers. Thus, the tracking of Milestone Dates becomes extremely important in order to minimize exposure.

When it comes to either OEM or TPM support, there’s no one-size-fits-all approach. Rather, the best approach is a hybrid strategy where Milestone Dates help determine what devices are best supported under OEM contracts and what devices ought to be moved to TPM.

Additionally, there is often a misconception that TPM support isn’t as cost-effective or reliable as the OEM, when in fact TPM can be as much as 70% cheaper with a quicker SLA than OEM.

The Hybrid Maintenance Strategy

In April’s case, the most feasible solution is an optimized hybrid maintenance strategy combining OEM and TPM benefits.

Hybrid maintenance involves manufacturers and TPM providers based on warranty period, equipment lifespan, budget, device’s place in the network hierarchy, and more. It’s essentially the best of both worlds for enterprises with direct hardware ownership, who get to pick and choose the best provider for their specific needs.

By leveraging a hybrid strategy, you are not forced by the OEM to refresh your network just because they determine the equipment is EOSL. By rolling those devices onto a TPM contract, you are free to extend the life of your network and save thousands of dollars on an unnecessary refresh.

A hybrid IT maintenance strategy results in optimized maintenance, making it possible to get the most value for money and allowing you to maintain your network on your terms, not the OEMs.

How to Determine Which Equipment to Put on TPM Plan?

To adopt a hybrid maintenance strategy, you must conduct a thorough asset inventory assessment and determine which devices need TPM support and which can continue maintenance with OEM.

The assessment process can be tedious and time-consuming, especially for large organizations with a global presence. You’ll need to determine and track years in service, end of sale (EOS), end of service life (EOSL), number of repairs, etc.

It’s not hard to see why an enterprise may hesitate to adopt a hybrid maintenance approach, given that it requires upfront effort and organization of your entire estate list. However, optimizing maintenance contracts and the long-run savings make it worth it.

OneScan to the Rescue

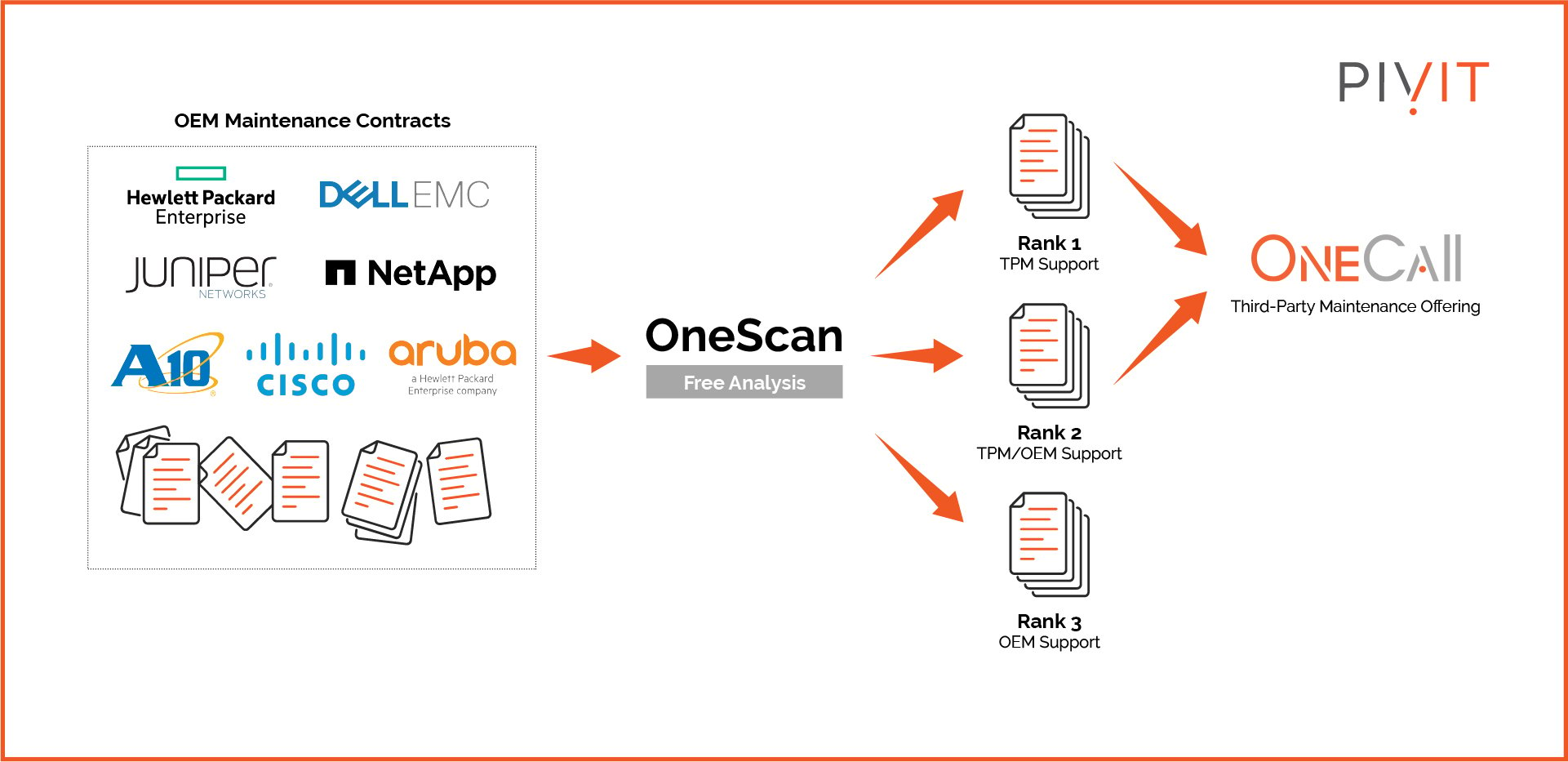

At OneCall (PivIT’s TPM offering), we help customers realize the benefits and cost savings of a hybrid approach every day. But we also realize that implementing this strategy can be a heavy lift and resource-intensive To address this issue, we’ve created OneScan, a completely complimentary service of organizing your estate list with Milestone Dates, important contract dates, and prioritization of equipment and their needed SLAs.

With OneScan, our experts will thoroughly analyze your entire estate list, uncover OpEx waste and provide you with a holisitic optimized hybrid approach for maintaining your entire network. And we'll do this all for free.

It’s a no-strings-attached service that helps you uncover OpEx waste, ensuring each device is maintained through the most cost-effective and optimized plan.

The OneScan Ranking Methodology

So how does OneScan determine which devices are better off with TPM and which should stick with OEM? OneScan ranks devices based on OneCall’s ranking methodology.

The ranking methodology features three ranks based on the years the device has been in use and the years it is supported by the OEM. Similarly, it also considers the client’s infrastructure strategy and technical dependencies.

Based on this methodology, each device is given a rank:

- Rank 1 devices should be supported by a TPM provider because they are no longer supported by the OEM.

- Rank 2 devices can be supported by the OEM or a TPM provider based on certain criteria.

- Rank 3 devices should be supported by the OEM.

The Rank 2 devices can be tricky to decide on as OEMs may cover them but not for long. In such scenarios, OneCall specialists will consult with your engineering team to determine the map out a plan for these devices.

We'll Do the Hard Work For You!

IT maintenance doesn’t have to be rocket science. It should depend on your business goals, strategy, and budget. A hybrid approach is the answer if you’re looking to uncover OpEx waste and need optimized, cost-effective support for all hardware. Combining OEM and TPM support has never been easier.

With OneScan, you have the blueprint for your hybrid maintenance strategy built for you. We believe maintenance should solve your problems, not create new ones. And OneScan does exactly that, for FREE!